Old Hickory Bat Co. Steps Up to the Plate

Bang-bang play. Caught looking. Can of corn. Duck snort. These are all phrases in baseball’s vernacular. But up on the ridge in Goodlettsville, it’s all about “Droppin’ Hick.” That’s the term players use when stepping up to the plate gripping a bat made by Old Hickory Bat Co.

Chad Lamberth and Jon Moyer started making bats in Lamberth’s grandmother’s garage in 1999. Back then, they did everything by hand, and their customers were primarily family and friends. But everything changed in 2000 with their first Major League customer, David Segui of the Baltimore Orioles. Today, they have a full-fledged company with 12 full-time employees plus their four-legged canine companion, Riley. And Major, Minor and Little League players alike are hitting it out of the park with Old Hickory Bats, including Mike Trout, center fielder for the Anaheim Angels.

“He’s becoming the face of Major League Baseball,” Lamberth says. “I’d like to have about five of Mike. This is a very tough business. You’ve got to stay on your game every day.”

The Business of Baseball Bats

Staying on their game is exactly what this Tennessee company has done to find success. Producing an average of 200 bats per day during baseball season, Old Hickory Bat Co. pays close attention to detail.

“To have a good wood bat, it starts with the log selection,” Lamberth explains.

And while the wood comes from the Northeast, “Bat billets are hard to come by,” says Travis Copley, vice president of sales and marketing. “When you find a good source, it’s to our advantage to keep its origin a secret.”

Upon selection, the wood gets split in Pennsylvania and turned to 3 ¼-inch thickness. “It’s sort of an old-fashioned process. We split the billets [little logs] like firewood, versus sawing. We feel it ensures the straightness of the grain, rather than the saw,” Lamberth says.

They are then sent to a dry kiln in Missouri, where the wood will dry down to a 6 to 8 percent moisture content. Back home in Tennessee, workers dowel the billets down to 2 ¾ inches thick and 36 inches long. The wood has come a long way but is now ready to turn into bats.

Aromas of hard maple, white ash and yellow birch permeate the air of the Goodlettsville workshop. Still, one wood won’t be found here – the company’s namesake, hickory. It weighs too much to produce quality bats.

Batter Up

“There’s a lot to point to Old Hickory around here,” Lamberth says. “You know Andrew Jackson was called ‘Old Hickory.’ They say he was real tough, and the hickory wood itself is really tough. It has a good ring, or should we say ‘crack’ to it.”

Hard maple comprises 85 percent of their bats, due to the tightness of the grains, density and durability that Lamberth and Copley feel is far more superior to the other woods.

Along the back wall are rows of billets with numbers scrolled upon their ends. These numbers, ranging from 4 to 6, denote the wood’s densities. While the 4-pounders will end up as fungos (which coaches use to hit ground balls), the 5- and 6-pounders will soon be in the hands of sluggers around the world.

High-Quality Bats

CNC (computer numerical controlled) lathes buzz in rhythm with the hands crafting each masterpiece from upwards of 1,200 patterns accumulated over the past 16 years.

“The only way to change the feel of a wood bat is to add or subtract wood to change the balance of the bat,” Lamberth says.

Once the bat is cut, it goes through an automatic sander and gets refined by hand. Silky to the touch, it’s ready for finishing. But not until it passes the ink dot test adopted by the Major League in 2009. Think of how a black marker might bleed on a tissue. This indicates a bat that could break and fly into the stands.

“The straighter the ink dot, the stronger the bat,” Lamberth says.

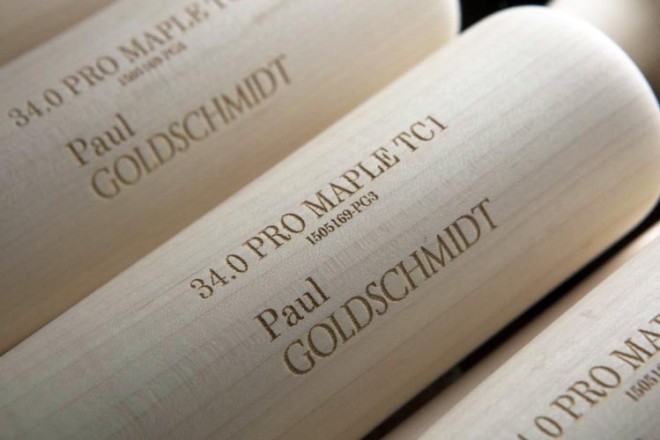

Once several coats of color and varnish dry, the bats are engraved with the model, length and, if applicable, player’s name. Considering Major League regulations require the bats to be in neutral shades, the most requested is black bats with unfinished handles or solid black.

Lamberth says that a Major League player may order up to 100 bats per season. “They may not all break, and they may not all come from us,” he says. “If they’re hitting good, it’s all them, but if they’re playing poorly, it’s because of the bat. It’s the nature of the beast. The players can be very superstitious.”

He notes that he’s really come to respect the sport. “When you’re playing baseball, it’s more than just a game. It teaches discipline, how to work hard and how to get along with people,” Lamberth says. “You have to work for what you get. If you’re not working as hard as the next person, you may be sitting. That’s just how life is. You have to work hard to keep your job. Just like in baseball, if you’re not hitting and you’re not fielding well, you’ll be sitting on the bench.”

Batter Up

Regardless of your stats, you can get into the game with your choice of more than 15 stock bat models for around $150. Old Hickory Bat Co. will even customize a birth announcement bat with an engraving of the name, size and birthdate. Visit oldhickorybats.com or call (615) 285-0588 for details.

I am very surprised with the story of the post, it is great

Love hearing about Tennessee small businesses, especially those that start out and grow to become like this one.